13

2025

-

10

What Is The Difference Between CPVC and PVC?

Polyvinyl chloride (PVC) is a familiar and versatile thermoplastic especially known as a piping and fitting material used for residential and commercial plumbing applications.

In the same thermoplastic family to PVC is chlorinated polyvinyl chloride (CPVC).

CPVC, though similar to PVC in name and available product types, exhibits superior resistance to heat and pressure, which enables it to be used in more demanding industrial applications.

The difference in heat and pressure resistance stem from the molecular makeup of each material.

Molecular Makeup of CPVC and PVC

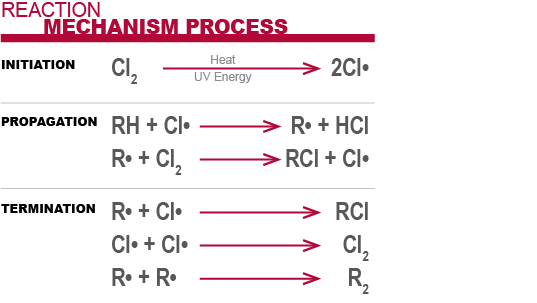

CPVC is a PVC homopolymer that has been subjected to a chlorination reaction. Typically, the chlorine and PVC react through a basic free radical mechanism, which can be initiated by thermal and/or UV energy.

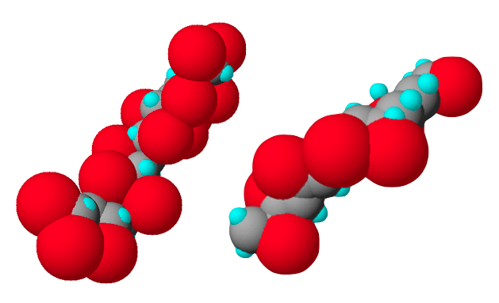

In PVC, a chlorine atom occupies 25 percent of the bonding sites on the carbon backbone, and the remaining sites are filled by hydrogen.

CPVC differs from PVC in that approximately 40 percent of the bonding sites on the backbone are filled with chlorine atoms. The chlorine atoms surrounding the carbon backbone of CPVC are large enough to protect its carbon chain from conditions that often weaken other thermoplastics.

The chlorine content of base PVC can be increased from 56.7 mass percent to as high as 74 mass percent, though typically most commercial CPVC resins contain 63 to 69 mass percent chlorine.

Diagram of CPVC (left) at a molecular level compared to PVC (right). The red spheres represent chlorine elements.

Temperature Resistance

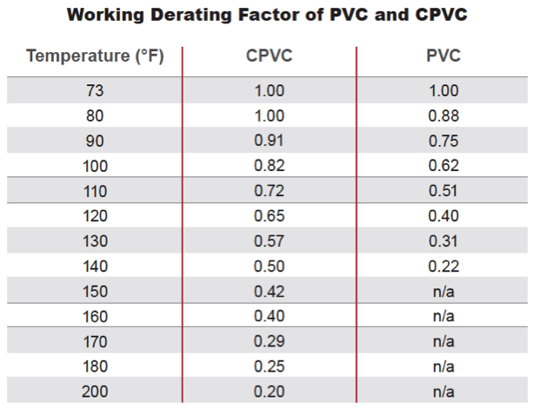

CPVC’s superior temperature resistance is exhibited in the ASTM standards for each material, as the maximum service temperature for PVC is up to 140°F (60°C) and for CPVC it is up to 200°F (93.3°C).

Pressure Resistance

PVC has a derating factor of 0.31 at 130°F (54.4°C), making it pressure rated up to 71.3 psi at that temperature (230 psi x 0.31 = 71.3 psi).

• CPVC has a derating factor of 0.57 at 130°F (54.4°C), making it pressure rated up to 131.1 psi at that temperature (230 psi x 0.57 = 131.1 psi).

Fire Performance

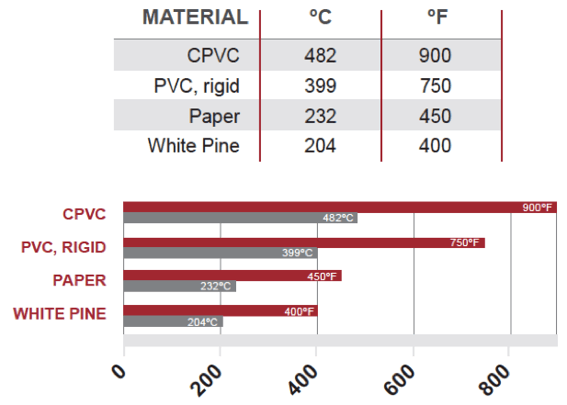

Flash Ignition Temperature: The lowest temperature at which sufficient combustible gas can be ignited by a small external flame. Corzan CPVC must be at 900°F (482°C) for this to occur, and rigid PVC must be 750°F (399°C).

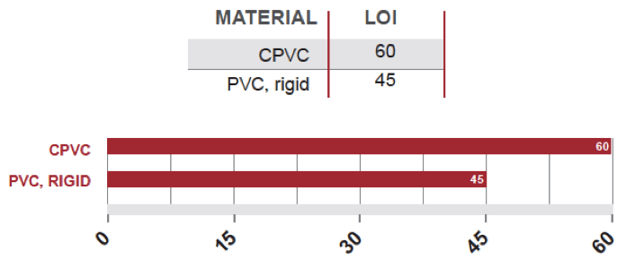

Limiting Oxygen Index (LOI): The percentage of oxygen needed in the surrounding atmosphere to sustain a flame. Corzan CPVC’s LOI is 60 and PVC’s is 45. For reference, Earth’s atmosphere is 21% oxygen.

Related News